This week’s question comes from Cody, who drives a 1966 Chevrolet Impala Station Wagon. Cody is curious about the differences between the three rear springs listed for his model. It’s likely that Cody’s wagon is a 2-seater, as this model typically uses three different types of springs, whereas the 3-seater version only uses two. Cody […]

Manufacturing Springs - Articles, Videos, and Physics

To properly manufacture springs, you need to match blacksmithing and physics to a vehicle's specific requirements. There is no such thing as 'one-size-fits-all' in suspension engineering.

Lucky for you, we do it all! Learn more about the process in the articles and videos listed below. Have your own question? Ask us today!

How To Interpret Ford Part Numbers

Ford part numbers are divided in to 3 sections – A 4-digit Prefix, the Basic Part Number andthen a Suffix The 4-digit Prefix breaks down like this – First Digit: Decade – C5ZZ5560D A = 1940’s, B = 1950’s, C = 1960’s, D = 1970’s, E = 1980’s, F = 1990’s, etc. Second Digit: Year […]

Rebound Clips Group Leaves To Make Them Stronger Together

Multi-leaf springs resist breaking thanks to rebound clips. Here’s why. What are those bands that are around your leaf springs? They are called rebound clips. A leaf spring does not break when it is being compressed, it breaks when the load is suddenly released. As the spring is being compressed with a load, each leaf […]

We Make Springs For Launch Pads, Tackling Dummies, and Wienermobiles Too

On this One Minute Monday, we look back at the extreme variety of applications we manufacture springs for. Not all our time is spent making springs for the vehicles we drive in shows. Besides the springs we make to keep your vehicle on the road, we have also made some springs for some very unusual […]

Why Shot Peening Is Important For Your Leaf and Coil Springs

Shot peening is when hundreds of thousands of round little steel balls bombard a spring’s surface during the heat treating process. Stresses naturally build up in the metal. The purpose of shot peening is to remove these inherited stresses. A spring that has been shot peened will last three to five times longer than a […]

Three Types of Leaf Spring

There are three types of leaf springs. Multi-Leaf Springs Multi-leaf springs are made up from heat treated strips of SAE 5160 Steel, in diminishing lengths, formed to a predetermined arch and held together by a bolt to the center. Mono-Leaf Springs Mono-leaf springs are a single heat treated plate of steel whose thickness is uniformly […]

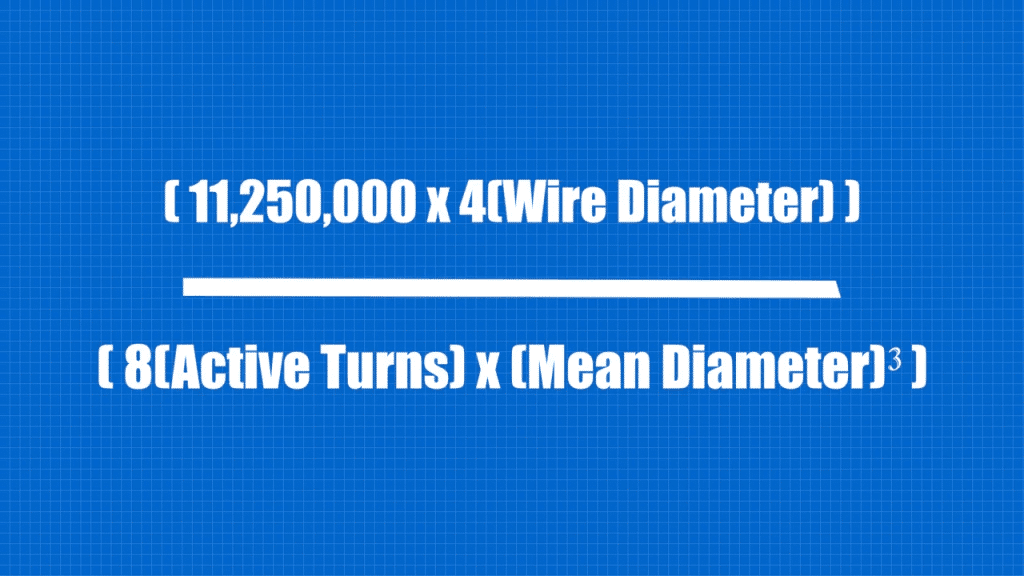

Calculating Spring Rate

Mike Eaton explains how to find your coils spring rate using a simple equation. This process is useful for those seeking to cut their coil springs, as it shows how cutting coils lead to a stiffer ride. (Hint: ordering new coils with custom specs, and you can preserve or even enhance your ride quality and […]

Leaf Spring Ends And Hysteresis

Which leaf spring end-type is best for trucks, and which end-type gives you the smoothest riding springs? There are three basic types: square, diamond point, and rolled. Square Ends Square, or constant thickness ends, are great for trucks, terrible for cars. It puts a concentration of all the pressure at the end of the leaf, […]

Coil Spring Ends

The three basic coil spring ends are tangential, square, and pigtail. Here, Mike Eaton shows you how to recognize each type. We have three basic types of ends: Tangential Ends The end of the spring twists off into space. If you try to stand this spring up on its end it will fall over. Square […]

What Are Tip Inserts Used For In Leaf Springs?

At the end of the leaves on many leaf springs, you’ll see what’s called tip inserts. The purpose of these inserts is to help reduce interleaf friction. Every manufacturer has their own idea on how they should look, how they should attach, and how they should be held in the spring. The video above has […]

How Coil Springs Are Made

Mike Eaton explains how coil springs are manufactured on this One Minute Monday.

How We Make Our Leaf Springs (6 Minute Video)

All About Our Spring Steel

Springs can’t be made from just any metal. They need to be made from a steel that has a high yield strength, helping it retain it’s original shape after significant pressure is applied. Surprise, surprise: a spring’s steel needs to be able to bounce back. So what type of steel would be perfect for building springs? […]

How Leaf Springs Are Made

We manufacture leaf springs all year long, and one thing everybody who comes to the shop wants to see is how it’s made. Well, not everyone can make it out to Michigan and Trumbull in Detroit, so we made this six minute video with Jeff Ford of Autorestomod to give you a special look into […]

Never Weld Springs (Do This Instead)

Why shouldn’t you heat up springs? For safety’s sake.

Spring Rate Vs Load Rate

Understanding spring terms will make your suspension build a thousand times easier.

Mono-Leaf Springs

Are mono-leaf springs dangerous? Only if you buy from the wrong people.

Rearching C1 Corvette Springs

I have Corvette leaf springs with grooves. Can we restore them or should I have new ones fabricated?

When Do I Install Coil Springs On A Hot Rod? What Do I Do Until Then?

Mike, I recently purchased a 1934 Ford 3 window coupe replica. To make a really long story short its an older kit that just never got put together, but in an excellent condition. My first order of business is to get a rolling chassis. The build book that was provided by the manufacturer calls out […]

Leaf Liners, Powder Coat & U-Bolt Torque

Mike, I wish I had read your tech page about two months ago. I just had my leaf springs powder coated and I’ve re-assembled the front springs with poly liners between the leafs. Am I correct in assuming that your advice for nothing to be between the springs also applies to these poly liners? If […]